PAT Testing – Everything you need to know

Portable Appliance Testing (PAT) is the process of examining the safety of portable electrical equipment and appliances to ensure that they are safe to use within a working environment.

Why is PAT testing important?

PAT testing is extremely important in ensuring that your appliances are safe. Employers must ensure the health, safety and welfare of all employees (Health and Safety at Work Act, 1974), with a failure to comply potentially resulting in legal action.

By having a PAT test completed by one of our excellent professionals, you can ensure that your appliances are consistently functioning at a high standard of safety.

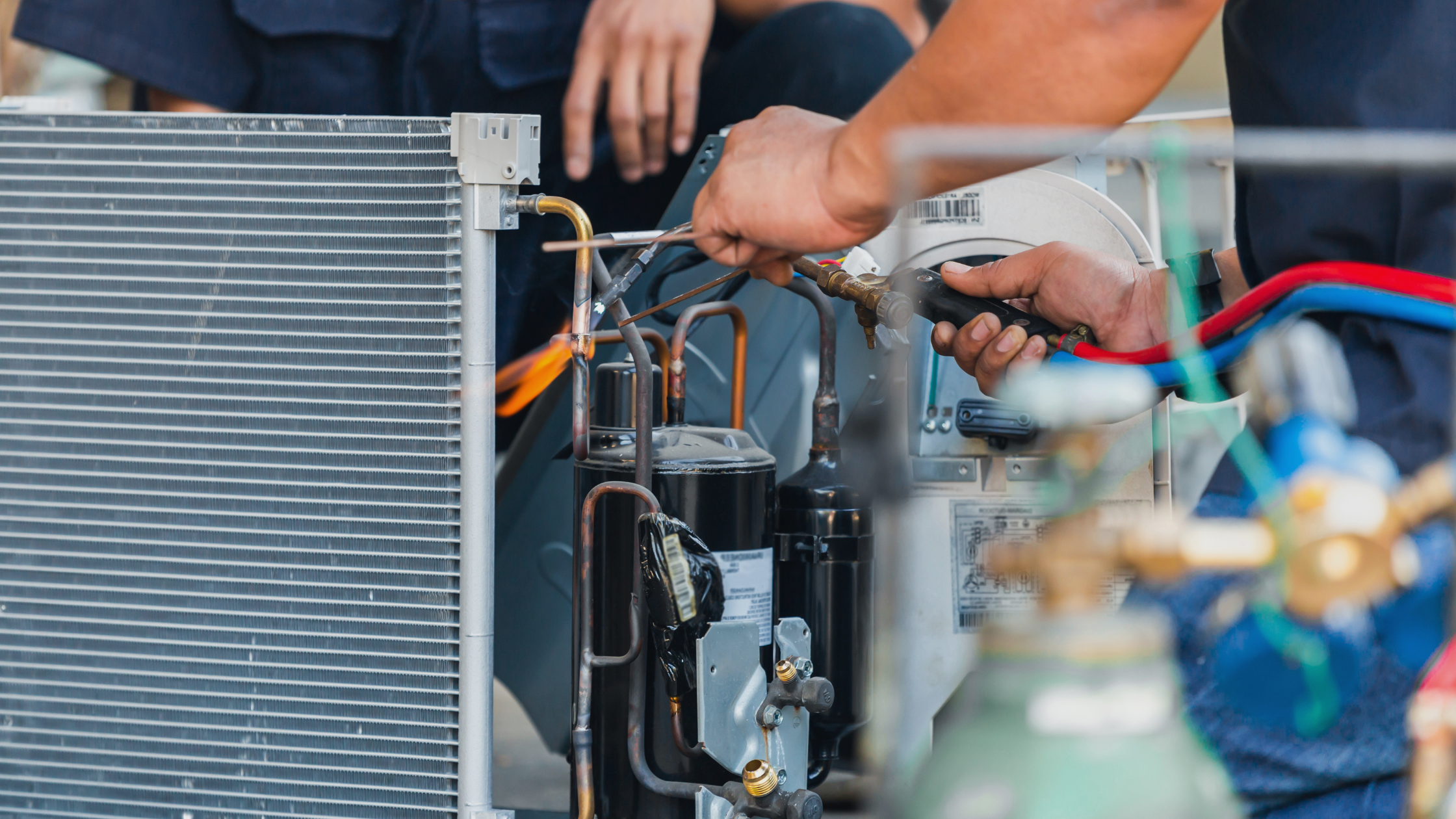

The PAT testing process

It is advised that electrical work must only be performed by qualified professionals, who have the knowledge, skills and experience needed to ensure that themselves and others are kept out of danger.

The HSE (Health and Safety Executive) advises that PAT testing should include three specific steps: user checks, a formal visual inspection, and a manual PAT test using a portable appliance tester.

Let’s discuss more about each step:

Step 1: User checks – Companies should ensure that all employees who use electrical equipment have basic training in the safe use of the equipment and how to identify any danger signs that they should be aware of. This includes any signs of damage or any potential risks such as water hazards or trapped cables.

Step 2: A formal visual inspection – A formal visual inspection must be carried out before the manual PAT test, while appliances are turned off and unplugged. The inspection should include checking the plug, the cable, the appliance, the mains socket, the Residual Current Device, and the environment that the appliance is in.

Step 3: The manual PAT test – The PAT tester will test the appliance to ensure that their performance stays within the safety parameters. This includes several types of tests, such as an earth continuity test, a load test, bond test and an insulation test.

The appliance will receive a ‘Pass’ or ‘Fail’ sticker, and the result should be recorded for future reference. Failed appliances must not be used again and should be removed immediately. If the appliance is repaired, it must pass another PAT test before it is safe to use again.

How often should PAT testing be done?

Currently, there are no specific requirements regarding the frequency of PAT testing your electrical appliances. It is the responsibility of the person responsible for electrical equipment to decide the frequency of the PAT testing in regards to an assessment of the risk-level of the equipment. The risk-level of the equipment should be decided based on factors such as the type of equipment, the frequency of use and the risk-level of the working environment in which it is being used.

Can PAT testing damage your appliances?

If the PAT test is correctly carried out by an experienced and qualified professional, the PAT testing process will not cause any damage to your electrical appliances.

What are PAT test certificates?

You will be provided with a PAT test certificate by a PAT testing specialist, after the appliances have been tested. This certificate can be used to prove the company’s compliance to insurers, regulators and staff.

At Bry-kol we specialise in expert electrical PAT testing across the UK, our team ensures compliance with Electricity at Work regulations while also aiding in lowering insurance premiums. Partner with us for thorough and reliable testing services.

Contact us on: 01782 577991 or info@bry-kol.co.uk